SAP Production Planning & Manufacturing (SAP PP) comprehensively covers the business functionality for production planning and controlling the production of goods and services. This module supports, among other things, various types of production planning. There are many possibilities and each of them supports a variety of approaches to planning and production processes, such as long-term and short-term planning, material requirements and production capacity planning, make-to-order and make-to-stock production.

In order to support various business processes in the area of production planning and control, it is necessary to define a whole range of master data within the module. One of the most commonly used data categories is the bill of materials (BOM).

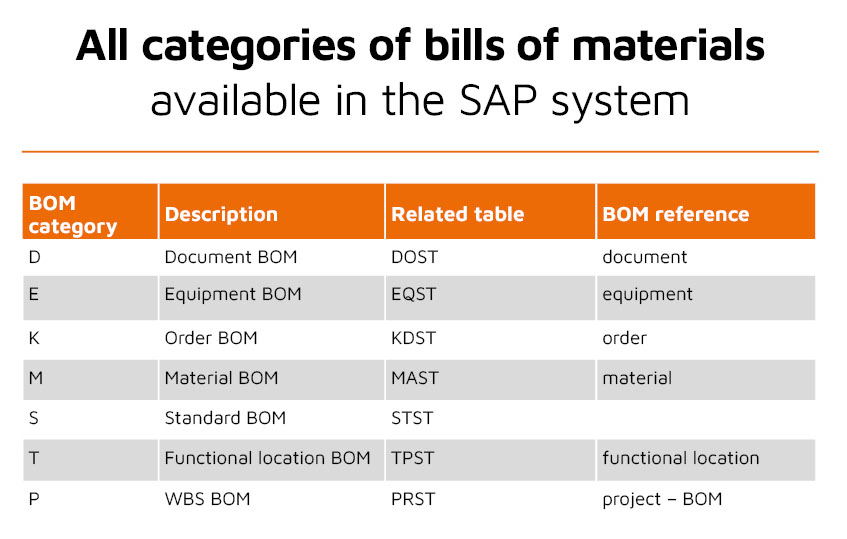

In terms of the structure, the bill of materials is a combination of components and their quantities required to produce basic quantities of a finished or semi-finished product. The bill of materials is often compared to a cooking recipe in terms of its ingredients. Such an analogy makes it easier to visualize its task. It can refer to materials, sub-assemblies or even parts as components and to production structures. Technically, bills of materials are included in numerous database tables, the most important of which reflect the bill heading and its items. A brief list of key tables for bills of materials is presented below.

- STKO – a table storing header data,

- STPO – a table storing item data,

- STAS – a table with selection of items,

- STPN – a table with control data,

- STPU – a table with subitems,

- STZU – a table of permanent bills of materials.

These tables are linked together by key fields that combine them into a logical whole and allow them to present the complete information required for use in the planning and production process.

The main key fields of material structure tables are:

- STLTY – a BOM category,

- STLNR – a BOM number

- STLAL – an alternative.

Here is an example. By reading the bill of materials with the number STLNR = 123XYZ, we send to the database a query to read a set of tables with all data for this particular bill. It should then be remembered that the BOM number does not define it completely when it is read because it may have different categories depending on its purpose.