Planning and preparation

Working out the method of implementation and its organizing in all dimensions (activities, people, resources, tools, effects, etc.) is a key element according to the project methodology of SNP Poland (now All for One Poland) – Go Forward. Its aim is a better result of the project, and the methodology itself is an important element of our organization’s workbench. Similar principles are followed by Forte. This allowed a joint road map to be created as a kind of migration project guide, which included a clear division of the parties’ responsibilities for particular tasks along with a schedule of their implementation. For a manufacturing company like Forte, timeliness and solidity of workmanship is the basis for effective business management. Planning had to take into account the specific requirements of the industry, the system downtimes, and finally, detailed tests confirming the effect of the project, i.e. a functioning system enabling progress in the company management. The plan created together was clear, realistic, modifiable and fully controllable in terms of progress.

Teams consisting of Forte employees and SNP consultants – technological and modular from the business areas used in the factory – were appointed to implement the project. The whole process was managed by a duo of project managers on the customer’s and SNP’s sides.

SAP on the IBM and Series platform

As a manufacturer of high quality software supporting all business processes, SAP delivers its solutions on several system and database platforms. One of the systems certified by SAP is the IBM System i. SAP provides a set of applications using an integrated relational database, security mechanisms, Web services and other operating system mechanisms, such as storage or a network.

The first version of the SAP R/3 system on the IBM platform was delivered in 1995. Since then, all subsequent versions of SAP applications have been available for the i system, including new functionalities based on SAP Netweaver ABAP and Java.

IBM’s PowerVM is a solution that makes full use of dynamic logical partition mechanisms (LPAR) that enable the division of resources of a single physical machine to several logical systems. Hardware resources can be allocated statically or dynamically. The use of LPAR in the SAP environment is a very effective mechanism that allows for the best possible utilization of resources.

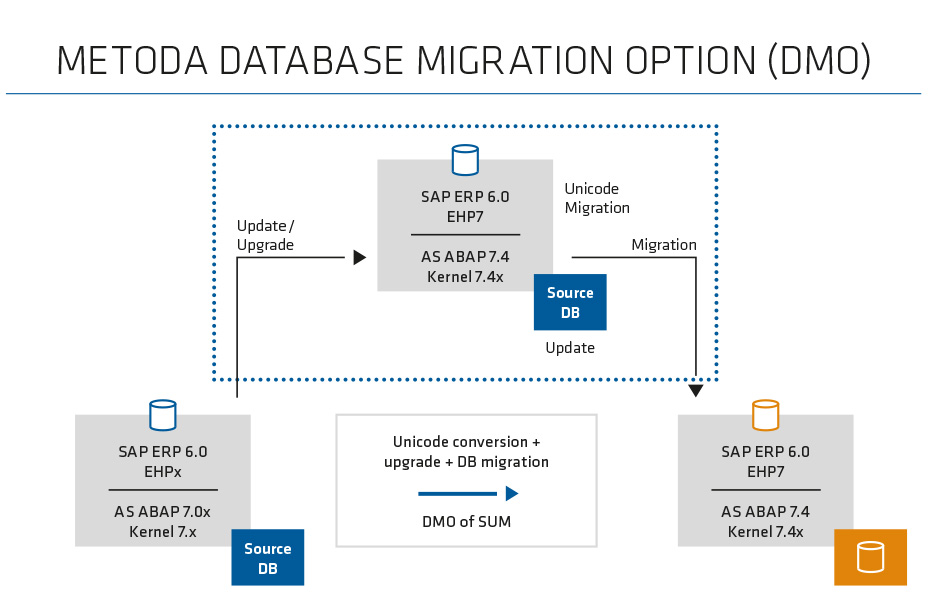

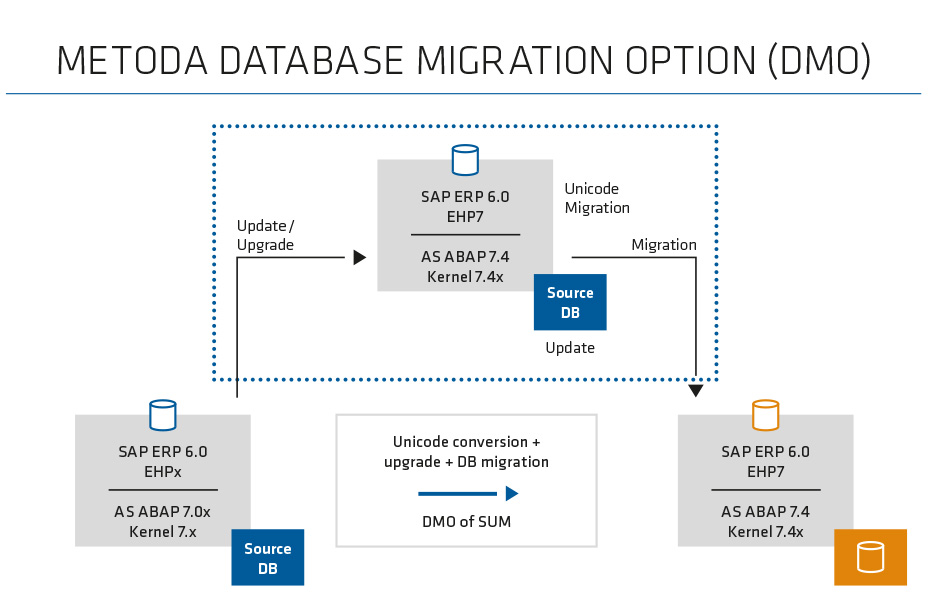

At an early stage of planning, it was established that the version of the ERP system that Forte had did not allow for its direct migration to the HANA platform. It was necessary to upgrade SAP ERP to at least 6.0 EHP7 version along with the conversion to Unicode. This was planned to be done in one step using Database Migration Option (DMO). This approach made it possible to shorten the project duration through a one-step technological transition from the source system to the target system, and thus customizations and functional tests could be performed once after each system migration. When defining an upgrade path, it was verified whether additional solutions installed could be upgraded to required versions and whether they could interoperate with HANA. The potential impact of the migration on the operation of reports and extensions from user namespaces was also verified.

In order to guarantee and confirm the required quality of the migration process, detailed test scenarios covering all business functionalities used in Forte were planned. The process of preparing scenarios and their subsequent implementation was primarily the responsibility of the customer with an advisory role of SNP (now All for One Poland). When designing tests, it is necessary to have a perfect knowledge of the organization’s business processes. This significantly reduces unknown and unpredictable factors before the target migration of the production system.

All project activities resulted in a migration plan that was neither too general nor too detailed. It allowed for the precise measurement of the progress of work in order to identify deviations, but at the same time it also enabled corrective actions to be taken by shifting actions or changing their order.

Infrastructure changes

After determining the upgrade vector, the sizing of the hardware for SAP HANA systems was started. It is a very important step in applying an in-memory solution. If the required RAM is underestimated, it will not be possible to load all the migrated data, and thus to launch the systems after the migration. During this operation, a standard SAP report running on each system was helpful. Its task was to determine the estimated size of the database on the HANA platform. The report takes into account the uncompressed volume of data, in this case in the DB4 database (IBM DB2 for iSeries), and calculates the estimated size of the compressed database on the new platform.

On the basis of the calculation, a decision was made to purchase a technology platform enabling the launch of new systems according to defined assumptions: high availability within a geographical cluster (two server rooms) with full redundancy of the platform and network infrastructure. Certified servers (Appliance) and servers for the virtualized environment of SAP application servers with an accompanying infrastructure, such as SAN and NET switches, were selected. A new efficient backup system based on EMC DataDomain solutions and NetWorker software was also designed for the new solution. The required infrastructure was provided by SNP Poland in cooperation with our technological partner DELL. Forte’s representatives were actively involved at the stage of planning and launching the new platform.

Migration of the environment

Once the migration plan was established, its implementation began. The first step was to install and configure the IT technical infrastructure as a hardware platform for the migrated environment. A technical team consisting of Forte employees and SNP consultants integrated the entire environment, embedding it in the existing infrastructure. As part of the works, the technical assembly of servers and the accompanying infrastructure was carried out. A redundant network environment with aggregated links was created. Both server locations were connected. Operating systems were installed and a virtual environment was created as a base for application servers. Finally, the entire infrastructure was connected to the new backup environment.

As the source version of the system needed to be upgraded, the next step was to define an exact vector. This involved determining how the upgrade would proceed and what components would be upgraded and to which version. This step was carried out with the use of Maintenance Planner, a tool delivered in the cloud by the SAP application manufacturer. This software allows for simple and effective planning of all changes in SAP landscape versions, as well as preparing a basket of media and downloadable patches, and defining an XML file containing information about the upgrade vector.

The migration procedure was performed in accordance with the methodology recommended by SAP, using Software Update Manager (SUM) and starting with development systems. The DMO procedure was selected to allow a combined upgrade, conversion to Unicode and migration to the SAP HANA platform to be made in one step. This method allows a system located in a traditional relational database to be transferred to an in-memory database provided by SAP. Using this method, the downtime of the source system is shortened to the time necessary to transfer application data after the upgrade process carried out in the so-called shadow instance has been completed. Thanks to this approach, the source system is available in an uninterrupted manner during this process. Unavailability begins with the start of the application data transfer, and the data itself is converted to Unicode on the fly.

The conversion to Unicode requires a thorough process of preparing the source system, as well as the required steps to be performed in the target system. The most important step in the target system is to adapt the programs to the operation in the Unicode environment. This requires the Unicode flag to be activated in the report to be converted. Most of the programs delivered in the SAP standard have this flag activated by default. Changes are most often required for programs from the user namespace for which the Unicode flag was not activated at the creation stage. Such activation may force the adjustment of the program code to match the syntax reserved for Unicode programs. The programs were adjusted to Unicode in the development system after its transfer was completed.

The migration process of each system ended with a thorough verification procedure, including technical and application tests.

Before commencing the migration of the ERP test system, it was updated by making a production copy. As a result of this action, the duration of individual upgrade phases was quite precisely determined, which allowed the estimation of future unavailability of the production system. Special attention was paid to the performance of thorough post-migration tests. The accuracy and unambiguity of the tests were the responsibility of the customer’s representatives. If any errors or irregularities were detected, they were immediately corrected at their request, and the tests of this element were repeated. The Forte team was actively involved in correcting and modifying its own SAP reports. After the completion of all tests, the readiness to carry out the production migration was confirmed.

Based on the obtained results, an hourly plan of upgrading the version and moving it to a new database for the ERP production system was prepared. Furthermore, the upgrade of each system was described in detail in the work report, including the duration of the individual phases. The descriptions contained information about the problems that occurred and the ways of solving them. This made it possible to carry out the migration procedure of the production system within the assumed time frame without any problems.

At the planning stage, it was decided that high availability for the production system was required. For this purpose, two reliability clusters were created; at the database level and at the application server level.

The main database cluster was launched based on the High Availability Extension (SuSE HAE) and replication of the basic node of the HANA production database to the backup node. The backup node server is also a platform for a development and test database. When configuring an environment in which a backup node has an additional function, it is necessary to close all additional databases during a switchover in case of failure. The cluster was configured in accordance with these requirements. When a basic node fails, the cluster service first stops the databases for the development and test system and then switches the production database to the backup node.

During the implementation, the same care was taken to ensure high availability of application servers. The configuration was based on Microsoft’s Failover Clustering technology. In the launched configuration, two application servers with a floating ASCS service were defined. In case of failure of one of the virtual servers, the Microsoft cluster switches ASCS to the other node, thus ensuring the availability of the environment with one running application server. This impacts the overall degradation of system performance, but ensures the continuity of system operation.

Prior to the production migration, full reliability tests were performed for various failure scenarios. In order to ensure credibility and unambiguity of tests, as part of the cluster, a full-scale SAP environment resulting from the test migration of production was launched After confirming the correctness of operation and acceptance by the customer, the final production migration of the SAP ERP system was commenced. Precise procedures verified during the pre-migration procedure allowed the migration to be performed without errors and within the assumed time. Precise scenarios of technical and application tests were used to verify the production system after its upgrade. The correctness of the upgrade was confirmed by Forte and the systems were made available to end users.

During the last stage of the project of migration to SAP HANA, recovery tests were carried out using the new back-up infrastructure. As part of the tests, both the database and application servers were recovered. Successfully completed tests confirmed the readiness of the environment to support demanding business functions while maintaining its high availability and security.

Tomasz Krawczuk, Project Management and Supply Chain Director, Forte Furniture Factory

A project and administration in a package

The tasks of the implementation partner did not end for us with the go-live. We have acquired a new hardware and software platform, but the period of building new team competencies is a long and engaging process. For this reason, we decided for remote administration of new systems by experienced SNP Poland (now All for One Poland) administrators, thus ensuring for ourselves not only the support for the systems, but also proactive optimization activities and individual consulting.

Tomasz Krawczuk, Project Management and Supply Chain Director, Forte Furniture Factory

Target achieved

It is the essence of cooperation between organizations to be able to use the potential of a reliable partner and to be guaranteed that the work entrusted to them would be carried out in accordance with the specification, on time and in budget, and with required quality. The aim of our activities was to achieve a better result, i.e. to provide a forward-looking system that guarantees better performance, enables the use of real-time processing capabilities and provides access to new functionalities that can make the management process even more effective.

The Forte project was a success. It confirmed that a good methodology and planning can be a guarantee of success. However, it should be remembered that the project was carried out by the customer’s employees and SNP consultants. It was their competence and commitment that determined the end result. This type of cooperation ensures that the benefits are always obtained by both parties; the customer, who was provided with the methodology compliant with best practices and measurable benefits of having the right procedures, and SNP (now All for One Poland) that can maintain a high quality of its knowledge and a high position in the market by preparing the knowledge to be transferred.

Fabryka Mebli (Furniture Factory) “FORTE" S.A. is a leading Polish manufacturer and exporter of furniture for self-assembly. The company was established in 1992, and in 1996 it debuted on the Warsaw Stock Exchange. The company has five production plants located in north-eastern Poland, including a chipboard factory launched in Suwałki in 2018, as well as a furniture factory in India. The total production area of FORTE is approx. 160,000 m2, and the warehouse space is 112,000 m2. The company offers a wide range of furniture for the dining room, living room, bedroom and youth room.

FORTE is a strong economic organization based on universal values: responsibility, development, cooperation and sensitivity. The company conducts activities with care and respect for the natural environment, following the highest quality and ethical standards.